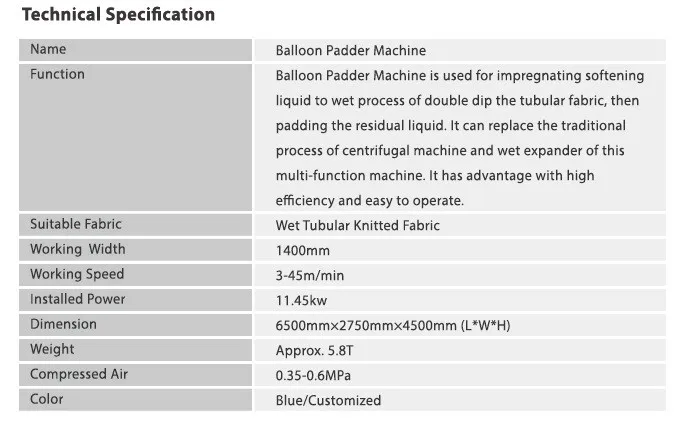

Breif Introduction

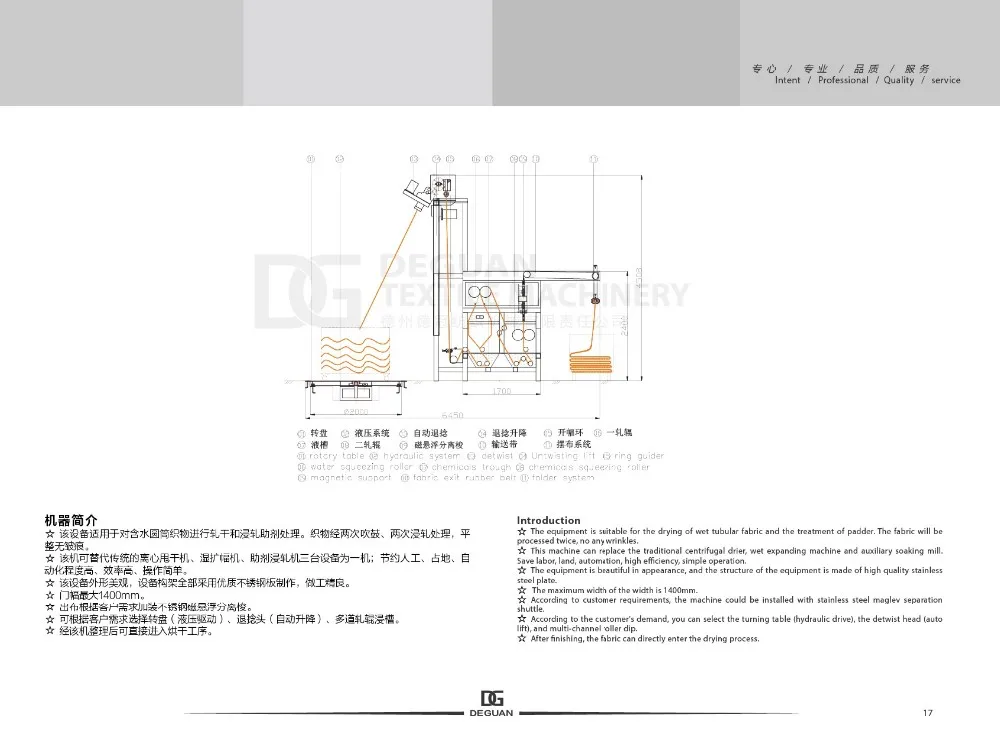

1. Stainless Steel Balloon Padder Machine is used for processing tubular fabric, especially the cotton material. It is high efficient and easy to operate.

2. The machine could detwist the roped tubular fabric after dyeing process. Then with the help of double dip, Balloon Padder could get the effect without any wrinkle on fabric. Turning table is driven by hydraulic oil through pipe connected with Pump. It can turn clockwise and anti-clockwise according to detwist purpose.

3. Based on the stainless steel material, now it is becoming more and more popular and important during the textile finishing process.

Main Features

1) Roped tubular fabric could be detwisted rapidly by the speed of 3~45m/min.

2) Wet fabric could be dewatered by his machine.

3) The speed and pressure could be adjusted through control panel.

4) Stainless steel material applied in this machine totally.

5) High efficient, easy operation, powerful 3in1, save your cost and creat more profit.